Transforming manufacturing operations with innovative technology solutions that optimize production, enhance quality, and drive competitive advantage.

Optimizing production processes, reducing downtime, and maximizing resource utilization in increasingly complex manufacturing environments.

Maintaining consistent product quality while meeting stringent industry standards and regulatory requirements.

Gaining end-to-end visibility into the supply chain to mitigate disruptions, reduce costs, and improve delivery performance.

Connected sensor networks and smart devices that provide real-time monitoring, predictive maintenance, and operational insights to optimize manufacturing processes.

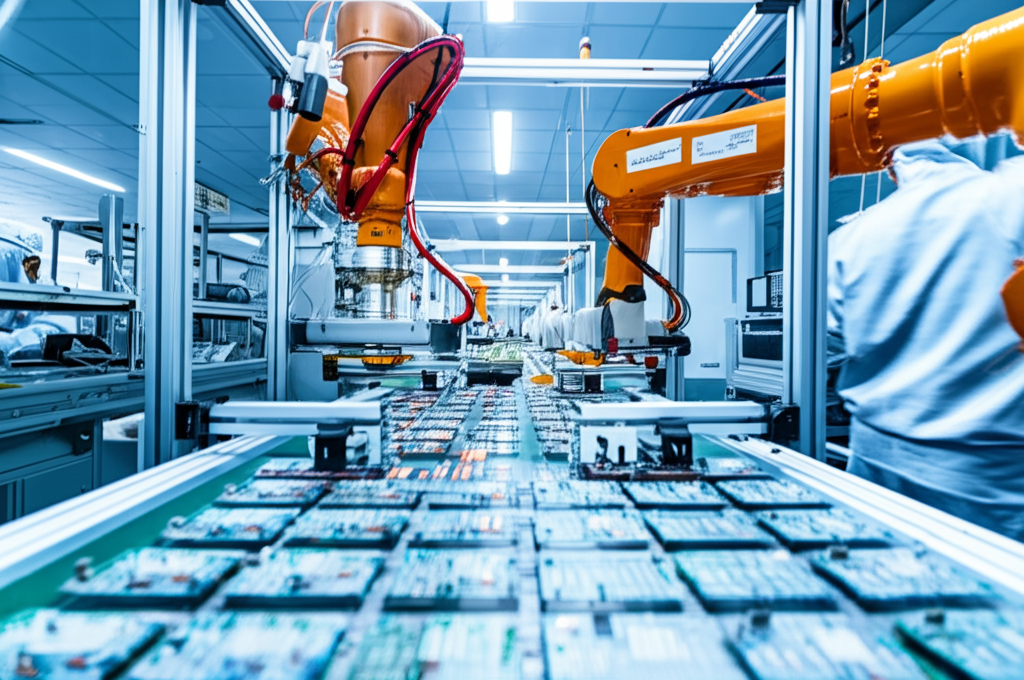

Integrated automation solutions that streamline production processes, reduce manual intervention, and enhance manufacturing flexibility and scalability.

End-to-end supply chain solutions that provide visibility, enhance collaboration, and optimize inventory and logistics operations.

Advanced analytics solutions that transform manufacturing data into actionable insights for continuous improvement and strategic decision-making.

Implemented an IoT-based predictive maintenance system that reduced equipment downtime by 35% and maintenance costs by 25%.

Read Case Study →

Deployed an AI-powered quality inspection system that improved defect detection by 40% and reduced quality control costs by 30%.

Read Case Study →

Implemented an end-to-end supply chain visibility solution that improved inventory accuracy by 45% and reduced stockouts by 60%.

Read Case Study →Our team includes specialists with deep experience in manufacturing technology and a thorough understanding of the unique challenges faced by manufacturers.

We understand that each manufacturing operation has unique needs. Our solutions are customized to address your specific challenges and goals.

Partner with Bytewise to leverage cutting-edge technology solutions tailored to your manufacturing needs.